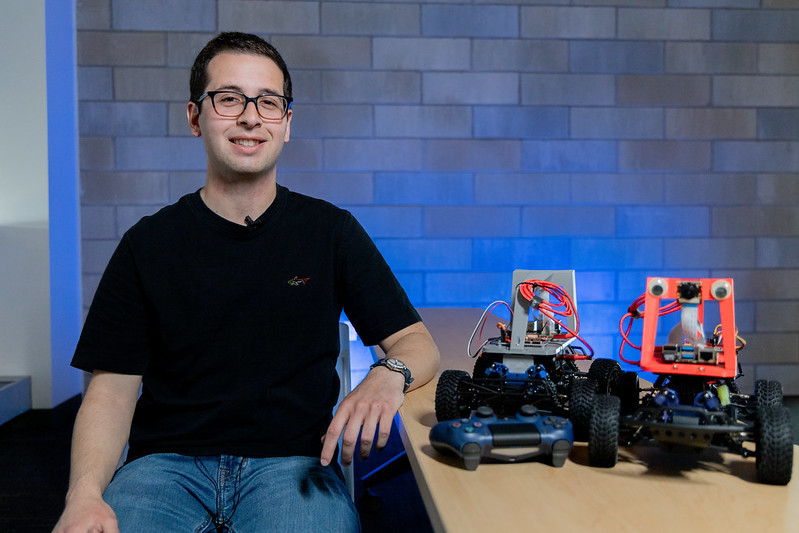

Today we feature Jack Campanella, a senior Electrical and Computer Engineering major with a minor in Computer Science and a concentration in Honors. Jack is a lab assistant and peer tutor, and he also serves as president of Rowan’s Robotics and Automation Society (RAS). He hails from Monmouth County, NJ. Here, Jack shares more details about the RAS club as well as his electrical engineering internship experience with OPEX Corporation, based in Moorestown, NJ.

Why did you choose Rowan University?

I chose Rowan after looking at a bunch of other schools, intending to become an engineering major. I ended up choosing Rowan because hands-on learning was extremely important to me. Not only learning the theory, but actually taking that theory, putting it into practice. Building those skills, whether they were hard skills, and they were super technical, or soft skills such as public speaking, writing or communicating, were extremely important to me. That way, I could ensure that I was not just growing as an engineering student, but I wanted to grow as a person and as an up-and-coming professional in the field.

That was a big factor in why I chose Rowan, as well as the location. I’m not really a city person. All of those factors showed me that Rowan would be a good school for me. There were a lot of opportunities for me to explore things on the professional side, as well as more on the social side, and interact with a bunch of people that I would get along with.

How did you choose your major among all the engineering disciplines?

When I applied, I was going to be a Chemical Engineering major. I went to a STEM high school focused on the natural sciences and biotechnology. Originally, I thought I didn’t really want to go into scientific research or get my Ph.D., but I did like the engineering side of applying it and still doing some research. I shifted toward chemical engineering because I liked how it combined chemistry, biology, and a lot of the math that I really enjoyed. But when I came to Rowan’s Accepted Students Day for engineering, I liked what the Chemical Engineering students were doing. But [ultimately] it’s not really for me.

So I kind of just decided, what else do I want to look at here? And I thought, “Well, I’ve heard a lot about the electrical and computer engineering program. Let’s go check that out.” So I looked at a lot of the projects, mostly the clinic projects that were going on with Rowan ECE, and I [thought], “This is something I can totally see myself doing.”

Thankfully, I fell in love with it quickly. I had some great professors that could get me excited about the topic. But really, at the heart of it, I just love engineering.

I have a bit of a coding background. Unlike some people in the program, I had no electronic background, but I thought the program was interesting. There are important skills I can learn that are a bit more general in engineering, at least from what I understood. I did a bit more thinking and then eventually applied to change my major, and the rest is history.

So I think I would have been happy with almost any engineering major, but I’ve really been able to enjoy it and I think excel in electrical and computer engineering.

How did you discover your internship at OPEX?

I knew about the company previously, because a Rowan student who was a couple years ahead of me had interned at the company.

I had always been interested in OPEX because it is a robotics company. That’s the specific discipline of engineering I’m looking to get into. So I kind of spent more time researching the company. I was fortunate enough to talk to them in person at the career fair this spring. That is how I discovered OPEX.

There was a lot with the company that I got excited about. Just seeing some videos and information they had online about the robots and the different things that they did, the problems that they’re solving.

From the first interview I had with them, I felt that interest from them, as well as within myself. I thought it was really cool. These are problems I can enjoy solving, and I can learn a lot from them. That’s the path that I started down with them.

Can you walk us through your day-to-day at OPEX when you’re on site?

It’s been a lot of variety for me, fortunately, because there are multiple products and systems at OPEX, and they’ve really focused on trying to get me involved with all of them, so I can kind of get to see all the different things going on with the company. So whether that’s getting ready for the day, working hands-on installing new sensors to upgrade one of our test machines we have in our own warehouse in the back, or getting involved with some documentation to figure out how are we actually going to distribute a change that we’re making out to the field for all our customers and clients, or sometimes even just working on simulation so that way I can connect lab equipment to components that we have that we need to test. That way, we can verify either the component lifespan or other potential issues related to the components that we may need to document.

Another task I am working on is a test box for OPEX robot and automation integration. This box works by providing a representation of the communication between OPEX machines and other outside devices and systems so that technicians can understand if integration issues are occurring because of OPEX products or other integration issues.

I’ve really immersed myself in my work and enjoy the day-to-day challenges I get to solve working on the electrical engineering team.

What has been the best part of your internship?

I think the best part of my internship has been getting involved with all the different parts of the engineering products that OPEX offers. This included being able to ask one of my coworkers a bunch of questions about the new Infinity system that they have for sorting and solving warehouse automation problems. Getting to see some of our customers’ facilities to see how our machines and warehouse automation solutions are actually implemented to understand what their problems are, and then how we are actually solving them and designing for that, has been really interesting to me.

Seeing the entire engineering process has been very rewarding because I feel like I’ve learned and heard a lot about that role. It’s been such a great complement to my education.

Can you talk to us about what you’ve learned in this internship?

I’ve definitely learned a lot in this internship — going through that troubleshooting process in a company to document it, to possibly hand it off to someone over email or through a conversation so that way they can run with it. Maybe I’ve never interacted with this person before, or they’re working in a completely different engineering department. I’ve somewhat experienced that at Rowan, but it’s definitely been a bit more laid back and relaxed. Seeing that now in a company, I’ve definitely had to make sure that I really check that I know what I’m talking about, and that I can communicate it clearly. I’ve learned about going through from one end to the other of being able to understand it, and then also explain it.

How has your experience helped you inside and outside of school?

I definitely think a lot of these skills I’m going to be bringing back to the classroom as far as the club that I lead, the Robotics Automation Society. I think the main things that I’ll be bringing back will be related to how we actually identify a problem. Talking to a customer or another engineer, and going through that identification process, really thinking like an engineer and saying, “What are we solving? What do we need? Do we have a timeframe? Is there a cost to that?” and bringing that context into the classroom, to see how that applies to a lot of the more technical knowledge that we’re learning.

To just understand the material, I think that’s something that’s going to be essential to bring back, as well as my technical experience, being able to work with programmable logic controllers with a lot of different wiring diagrams, as well as how you would integrate new sensors into a system that may have been established a long time ago. Working with older machinery or electronics that were designed by an engineer, maybe 10, 15 years before you, that’s not something I really had to do at Rowan. Being able to understand how you interact with that, break down the system that you’re working with, and figure out how you either update it or integrate it with something completely new is something that I encountered for the first time at my internship.

What advice do you have for students on internships?

What was really important was building a network. I kind of went down the route of making some new friends, trying to leverage my previous internship, connecting with people who maybe I had previously interacted with at that company, or talking to coworkers that I met through there, to see who they knew. I started posting a lot on LinkedIn. I found that was a resource that I see highly underutilized. Really, just going through that process of kind of being my own cheerleader, talking about the projects I’m involved in, the extracurriculars I’m involved in. Putting it out there, like, this is what I’m working on, so people can either discover me through LinkedIn, my personal website, or sometimes YouTube videos that I’ve done through Rowan.

I was able to pick opportunities and ultimately land on OPEX, where I was very excited about it. I liked the culture, I liked the problems they were solving. And it was more than just, oh, this is an internship where I can hopefully get some experience to put on my resume and pay some bills. I wanted to make sure that I found a company that I was going to continue to learn and grow from and hopefully add value to what they’re doing as well.

I think it’s really important to figure out what you’re excited about while you’re at that internship, because it’s almost a way to see what you are going to be doing once you graduate. I think that the process of finding a good internship or a good job doesn’t necessarily start once you start applying or once you start receiving offers, it really starts when you’re beginning to reflect on: What do I like? What can I do to do more of what I like? That reflection process while you’re there, as well as before you get there and after you get there, I think that’s really important.

It’s really important for any student, whether they’re engineering or not, to kind of leverage the opportunity of, you’re a student, you’re not expected to know things. So you can ask a lot of questions to people who are professionals and are more experienced than you. You can get some great answers.

What are your career goals or outcomes after earning your ECE degree?

I’m planning to either go into industry or possibly go on to get my master’s. I’m not entirely sure yet. That is something I’m continuing to explore this summer, as well as during my senior year.

The goal is to get to that point where I am able to be heavy on the design side, maybe research and development, because that’s really what gets me excited about engineering. I see it as a way for me to express my creativity.

Let’s talk about the Robotics and Automation Society (RAS). How did you find out about it? What is your role?

I first heard about the Robotics and Automation Society my freshman year as part of the Honors BLAST mentorship. My mentor, Matthew Beck, who was a previous SGA president, was a really great guy. He just graduated as a mechanical engineer. He told me about the Rowan Robotics and Automation Society, and he was super excited about it because he got a project funded to make an electric skateboard, [which I thought was] really cool.

I went to the first meeting. The presentation was great. In the next two weeks, we actually started to work on projects, and that absolutely blew my mind. I’m given this opportunity to learn, and actually try things hands on. There’s not really a fear of messing up or anything, and the community of people in the club was really strong and supportive, and there weren’t really any barriers. I did start to make some of my first friends, most of which I’m still friends with to this day.

The end of my freshman year, I decided to run for vice president, ended up winning an election, and then COVID hit. So that was a little awkward. Being online for a hands-on club was really difficult. And then finally being able to come in person again, that was an absolute game changer.

A little bit before that, I became the president of RAS. So in that leadership position, I was like, alright, well, we need to go full-steam ahead, shifting the budget. So that way we can look ahead and to have all these in person events or projects immediately when people come back.

Through my junior year I was basically just finding people who wanted to do projects but didn’t necessarily have the resources, and just having an honest conversation with them and saying, Hey, totally fine, you don’t have any experience in this. What resources do we have that can help you? Because I really saw the role of RAS, and myself as the president, was not really to fall into the leadership position but to kind of say, “Ok, I have access to a lot of these resources. How can I use that to improve the experience of other people of Rowan, while at the same time improving my experience?”

So really, the whole point has been just to find a win-win for everyone, keep going down that path. It’s been a major focus of some of my time at Rowan. And it’s been useful for me to leverage more opportunities for myself and leverage more opportunities for other people here.

Final thoughts?

I would definitely say that I’m very excited about my current position at OPEX. It’s definitely been a great opportunity for me to continue to expand my knowledge in robotics. It’s really been important to me, because I found that I had this interest in robotics. And while there is some support at Rowan for robotics, it hasn’t been as much that it’s something that I can absolutely completely dig into and sink my teeth in. So I’ve had to find opportunities for myself, whether they’re educational jobs or [something else], to really continue to expand my knowledge.

That’s one of the things I found very attractive about the opportunity at OPEX and why I decided to intern there. That way I know what topics I want to continue to focus on learning so that I can continue to build a career in robotics.

Interested in learning more about Robotics and Automation Society? Check our our video that features Jack here:

Like what you see?

Story edited by:

Rachel Rumsby, senior communication studies and public relations major

Joseph Conte, junior community and environmental planning major

Select photos by:

Tyler Allen-Williams, radio/TV/film major